Find Automatic Four-side Saw Machine, Plywood Four Sides Edge Machine, Plywood Making Equipment Cutting Saw on Industry Directory, Reliable Manufacturer/Supplier/Factory from China.

New Products

| Payment Type: | T/T,Western Union |

|---|---|

| Incoterm: | FOB,CFR,CIF |

| Min. Order: | 1 Piece/Pieces |

| Delivery Time: | 30 Days |

Model No.: XBG8656

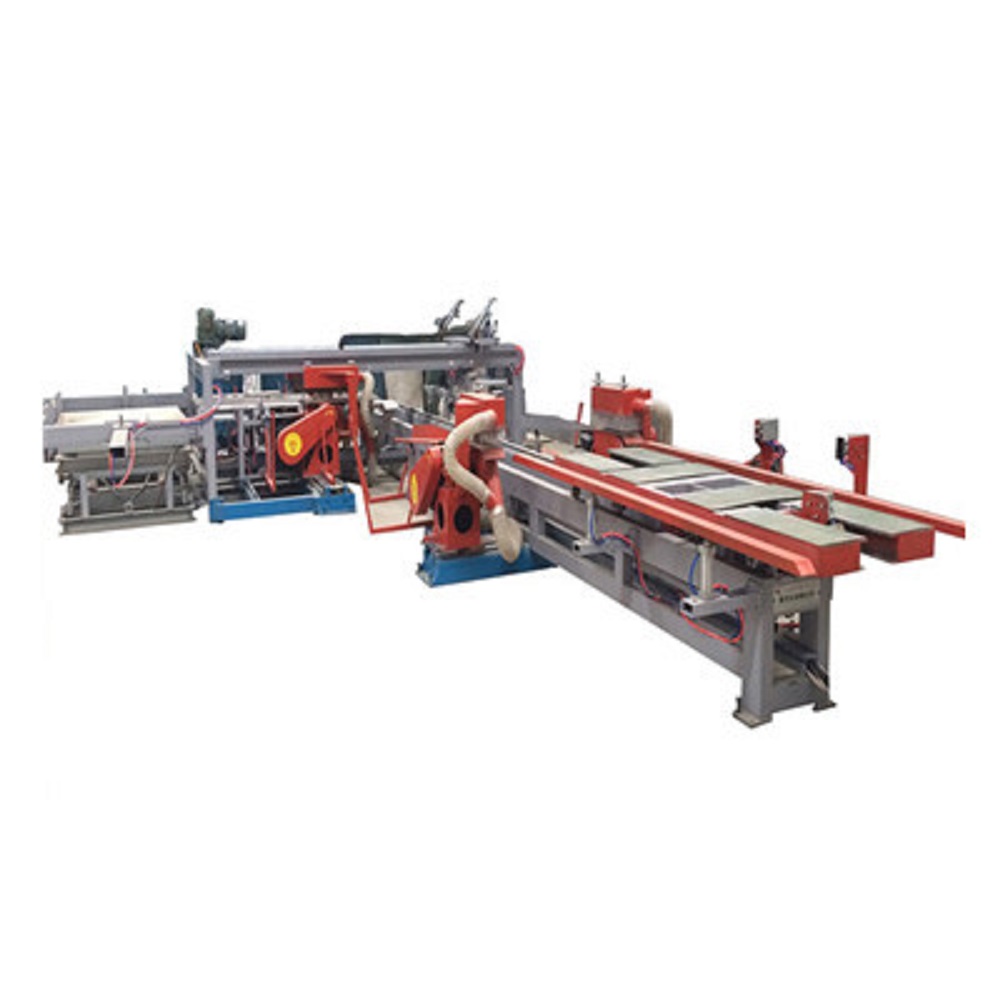

Automatic plywood four sides edge trimming machine cutting saw

Product Application

This product is suitable for plywood board, cutting edge technology is manual cutting to a great leap forward of automatic cutting,

compared with ordinary hand saws, the machine has five features: precision, high efficiency, energy saving, provincial industry and environmental protection.

The machine adopts PLC intelligent design, saw blade speed can be adjusted automatically according to cutting condition,no need to stop any saw blades,

at the same time realize the automation of stacking and leftover material removal, safe and convenient operation, smooth running, low noise.

Its high quality automatic saw cut, board face is smooth, no dozen edge, coastal zone size standards.

Highlight the native: intelligent cutting, smooth running safe, accurate and efficient.

Main Features

1. The main structure is strong with enough rigidity and high stability.

2. It has pre-loader device, the production capacity and efficiency is high: one shift working can produce 4000-5000(18mm).

3. This saw has high precision anti-wearing guide rail, high precision cutting.

4. All working process is controlled by PLC, cutting and stacking is automatic.

5. It has a device to clear the edge waste away automatically.

6. This machine only needs 2 workers, it can save the cost of labor.

7. This saw very good dust collecting system, it will collect all dust of the machine, and dust exhaust in strong force.

Servo motor, strong driving force, low power consumption. From the lowest to the highest speed, speed servo motor can run smoothly and strong ability of overload.

Full automatic stacking system to gurantee the whole trimming jobs process smooth and fast. Saving labors and time. It can stack and tidy the finished board in to bunddles.

factory describes:

Shandong qufu xingbang heavy industry equipment co., LTD will build a science and technology leading enterprise integrating research and development, manufacturing and installation, and international trade.

Main development and production of products are building materials equipment: automatic glass magnesium fire board production line, large multi-function wall board exterior wall insulation board production line, fire door core board production line of environmental protection and new energy straw making machine, fully automatic quadrilateral cutting saws;

Woodworking machinery, automatic cover machine, labeling machine, automatic finishing machine, UV light solid machine, hot pressing machine, vacuum molding machine, cold press machine, universal coating machine, and Other products, the above products have passed the relevant state departments of technical appraisal and recognition, has enjoyed good reputation in the market, obtained the customer consistent high praise.

The products produced by the company are sold to all over the country and some surrounding countries and have achieved high economic and social benefits.

Product Categories

Building Material Making Machinery

Compound Ventilation Tube Sheet Metal Production Line

Automatic Four Edge Cutting Saw

Large Fireproof Door Core Board Production Line

Fully Automatic New Compound Straw Tile Production Line

Fire Prevention Board Machine Straw Door Equipment

Fire Prevention Board Production Line

Polyurethane Low Pressure Foaming Machine

Polyurethane High Pressure Foaming Machine

Glass Magnesium Fire Prevention Board Plate Automatic Production Line

Glass Magnesium Fire Board Decorating Plate Production Line

Plastic Extrusion And Recovery Equipment

Plastic Extruder Machine

Plastic Pelletizing Recycling Machine

Sheet Plate Board Extrusion Line

Plastic Washing Recycling Machine

PVC WPC Profile Extrusion Line

Plastic Pipe Extrusion Line

Plastic Crusher & Granulator

Plastic Shredder

Plastic Auxiliary Machine

Woodworking Machinery

Wallboard Decorative Machine

Door Decorative Machine

Cabinet Decorative Machine

Floor Decroative Machine

Moulding Line Decroative Machine

Veneer Machine

Indoor Decroative Machine

Woodworking Wrapping Machine

Sawdust Granulator /Wood Pellet Granulator

Wood Door Vacuum Laminating Machine

Environmental Protection Equipment

Waste Gas Treatment Equipment.

Dust Removal Equipment

Plastic Injection Molding Machine

Plastic Injection Molding Machine

Plastic Blow Molding Machine

Product Categories : Building Material Making Machinery > Automatic Four Edge Cutting Saw